-

-

-

-

- Master's Choice Series

- Fermented Fresh Extract Intestinal Care Series

- Red Brick Series

- Golden Immune Series

- Wugu High Fresh Meat Series

- Super Series

- Nature Nutrition Series

- Fresh and Fresh Series

- Fermented Double Extraction Series

- High Quality Vitality Series

- Grain Free Raw Meat Series

- Fresh Journey Series

- Sparkle Series

- Low Temperature Baking Series

- Selected Original Taste Series

- Fermented Raw Meat Series

- Breeding Series

-

-

-

-

-

FACTORY INTRODUCTION

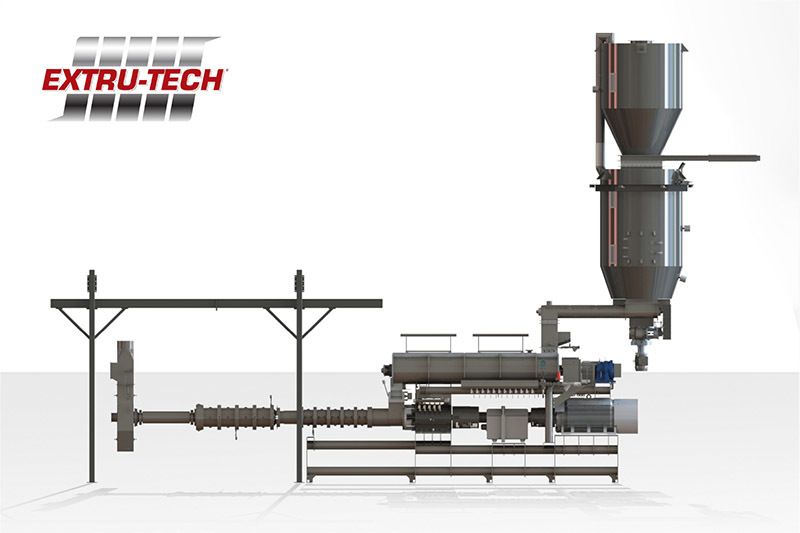

METZ Nantong Smart Factory is located in Nantong Economic and Technological Development Zone, Jiangsu Province. It was completed and put into operation in 2019 with a project investment of 500 million yuan and covers an area of 50 acres. The factory has introduced the world's top equipment such as EXTRU-TECH expansion units and Buhler automatic production solutions, and the annual production scale can reach 80,000 tons.

The import rate of factory equipment is 85%, and the import rate of core equipment is 100% to achieve safe, intelligent and efficient production, ensuring the high quality of every pet food.

Core Equipment Import Rate

Metz Smart Factory

Annual Production Scale

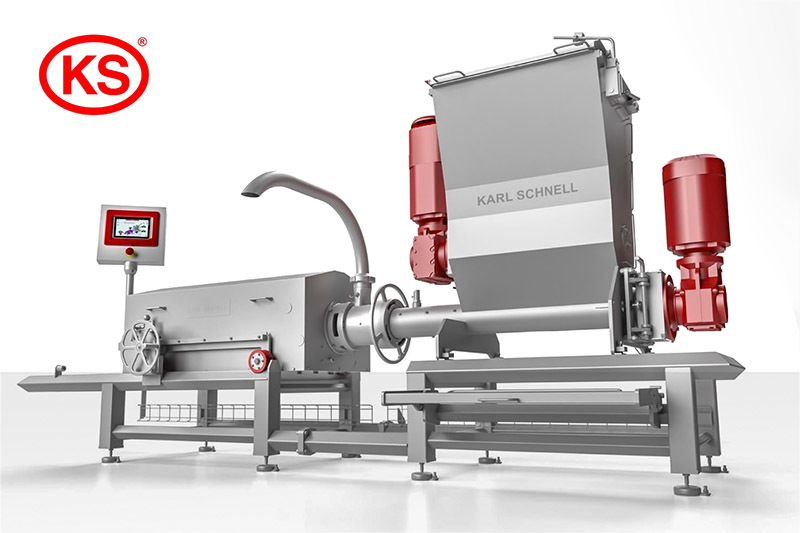

WORLD-CLASS EQUIPMENT

Extruder

American ET 10T Extruder Unit

Low Temperature Emulsifying Machine

German KARLSCHNELL Ultrafine Crusher

Spraying

Dutch DINNISSEN Vacuum Spraying Machine

Drying and Cooling

German GEELEN Dryer, Cooling Tower

Packaging and Palletizing

SYMACH Packaging Machine, Palletizing Machine From The Netherlands

Automatic Filling

German BOSCH Packing Machine

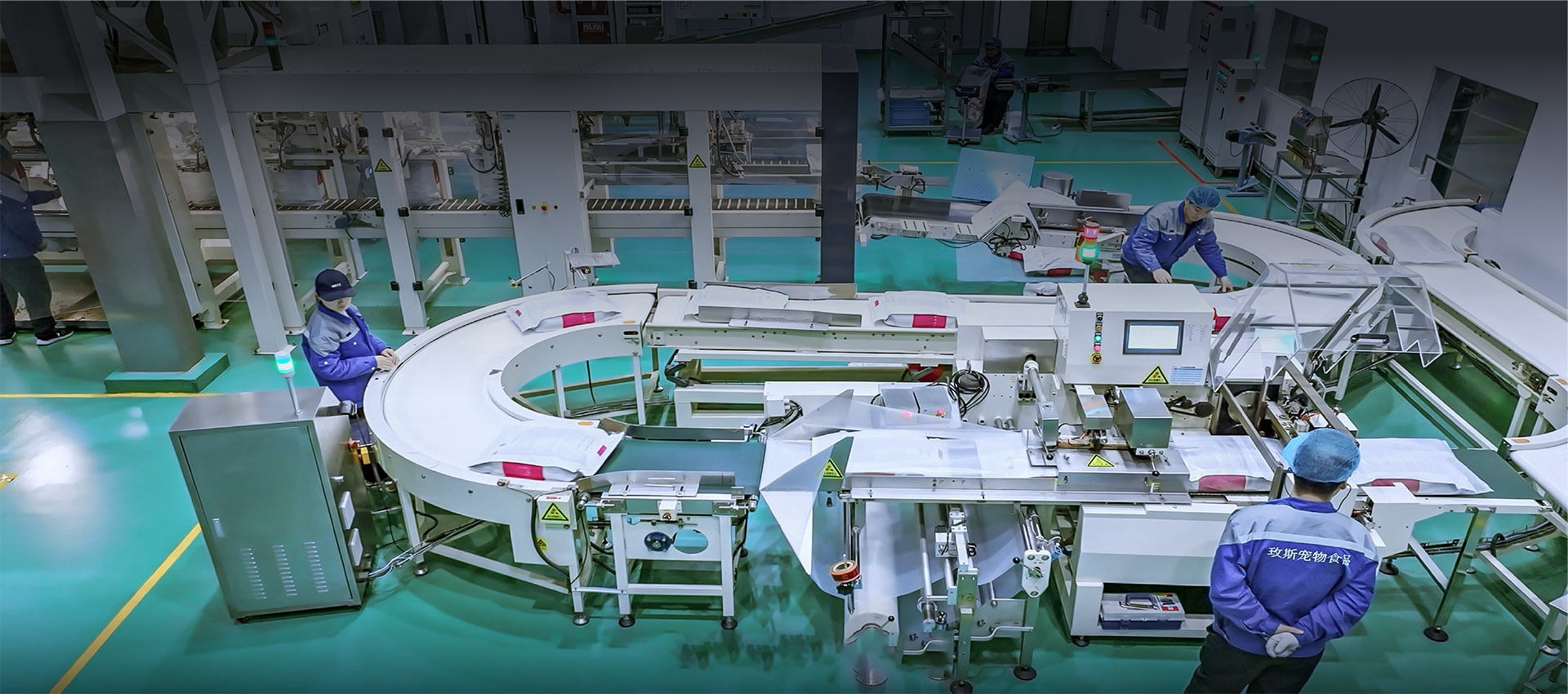

AUTOMATED PRODUCTION PROCESS

FRESH MEAT GROUTING TECHNOLOGY

METZ is the first pet food manufacturer in China to use the fresh meat grouting process.

Fresh meat grouting is the combination of fresh ingredients + advanced technology, so that pet food to retain more fresh meat nutrition and flavor, greatly improve the quality of pet food. Different from most of the domestic pet food using a large number of meat powder into food, Extru-Tech10T bulking unit bulking technology, is the first proposed and applied technical solutions in the field of fresh meat addition, not only fundamentally solve the problem of wet processing difficult products instability, but also through software optimization system control, improve the mixing performance of materials, improve product quality, Increase the amount of fresh meat added to 70%.

MULTIPLE INTERNATIONAL CERTIFICATIONS

* IOS9001 International quality system certification

* ISO45001 Occupational Health and Safety management system certification

* ISO14001 environmental management system certification

* US FDA registered facility

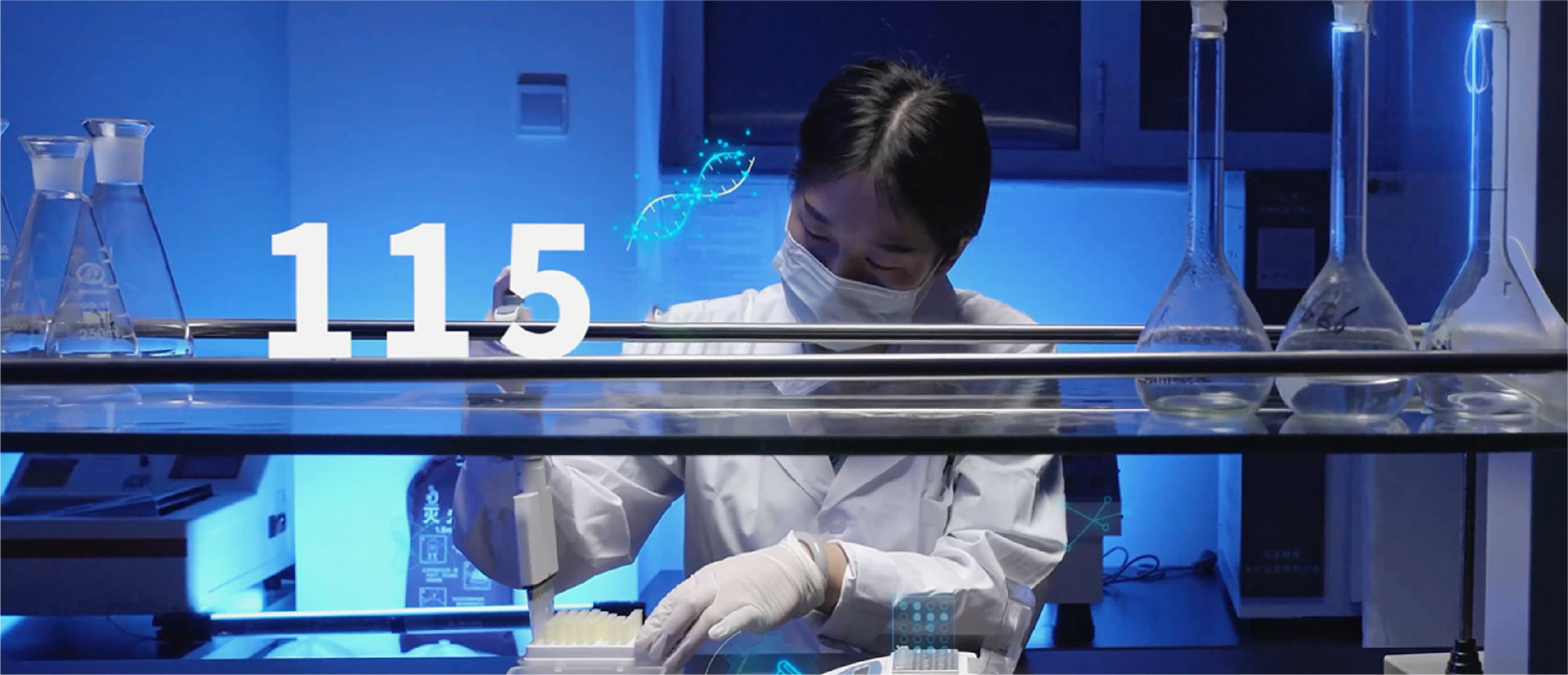

QUALITY INSPECTION, STRICT QUALITY CONTROL

Pre-Production Stage

115 tests of raw materials: The raw materials must be tested and completed, including inspection and quarantine certificates, material transportation equipment testing, freshness index of raw materials (volatile basic nitrogen ≤ 15mg/100g) and a series of nutritional indicators.

Middle Stage Of Production

Sampling inspection in the middle of production (30min/ time): real-time sampling of semi-finished products for routine eight items (crude protein, crude fat, crude fiber, calcium, total phosphorus, water-soluble chloride, ash) detection. Through the DA7250TM near infrared analyzer (only 6 seconds to complete the detection of physical and chemical indicators (infrared)), TVT6700 food physical properties tester, METTLER TOLEDO HE53 rapid moisture determination instrument.

Late Production Stage

Internal testing: Quality inspection center finished product sampling, sample retention internal inspection can meet the export certification standards of more than 30 test content, real-time control of product quality.

External testing: According to the different requirements of the product, the finished product will also be submitted to the inspection authority of the third party testing institutions, including the United States AAFCO, European FEDIAF, heavy metals, toxins and other testing projects

HIGH STANDARD PRODUCTION WORKSHOP

20 ACRES OF DOG AND CAT EXPERIMENTAL BASE

CONTROL INTEGRATED WAREHOUSING AND LOGISTICS

Tel:

E-mail:

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.